Supply chain management

Pearson purchases goods and services valued at over £2 billion each year. This total includes our investment in research and development such as our advances to authors and the development of new digital products and services.

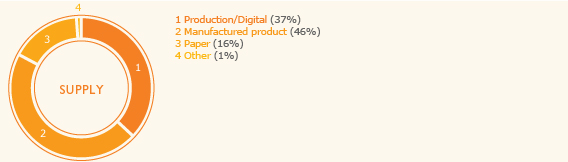

Although rapid growth in our digital sales is being reflected in the mix of what we purchase, paper and print remain the most significant categories of direct spend for us:

As we grow, so do opportunities to consolidate and centralise the way that we purchase goods and services. This will bring efficiency benefits and cost savings, as well as a consistent global approach to the way we select and monitor the performance of our suppliers across all aspects, including corporate responsibility.

Our approach

Pearson was a founder signatory to the UN Global Compact in 2000. We were clear from the outset that we had a responsibility to use our influence with our suppliers across our supply chain. So, in 2001, we made a series of commitments that covered labour standards and human rights as well as environmental responsibility, and extended these to cover our supply chain.

These commitments, together with the Pearson code of conduct, remain the guiding principles against which we judge our actions and performance today.

Labour standards, human rights, the environment and combating corruption

We have set out the commitments that we expect from all our suppliers.

Specific clauses relating to these standards are an integral part of our contracts for key suppliers. These standards include the rejection of forced and compulsory labour, a respect for diversity, a minimum age to work on Pearson projects and compliance with environmental and other regulations.

We write to all our main suppliers – defined as those where we purchase more than $250,000 or equivalent in local currency – to advise them both of our commitment to the Global Compact, and about the Pearson code of business conduct. Our 2010 process was completed in January 2011.

We carry out an ongoing programme of supplier visits to assess compliance with the Global Compact and with our own standards. These visits reinforce our commitment to the abolition of child labour and all forms of forced and compulsory labour, as well as environmental responsibility. Our production departments this year continued our programme of visiting suppliers all across the world.

We also work with industry partners on setting common standards that reflect the Global Compact principles.

| Global Compact communication | 2010 | 2009 | 2008 | 2007 |

|---|---|---|---|---|

| Over $250k | 1,882 | 1,867 | 1,702 | 750 |

Paper

Our books, newspapers and magazines all use paper. We lead the way in investing in new technology to provide opportunities for our customers and readers to access our content digitally. Nevertheless, we expect that our use of paper will continue to be an important means for delivering our products.

The amount of paper we use is determined by the news agenda of the day, our advertisers, the decisions taken by our authors and the number of products we commission, print and sell. We therefore believe it is unrealistic to set targets to reduce total paper usage. Instead, our role should be to incorporate environmental considerations into our paper purchasing processes.

We source paper primarily from North America and Scandinavia.

Paper is a priority issue within our wider programme of considering the environmental impact of our supply chain. We:

- First adopted and publicly disclosed our environmental policy with regard to paper sourcing in 2003. This policy was updated in 2008;

- Collect and map data on the forest of origin, certification systems applicable and recycled content for the papers we purchase;

- Hold regular training sessions for our production teams around the world on both labour standards and environmental responsibility issues. We ran sessions in 2010 with the Financial Times Group, Penguin in New York; Pearson Canada and Pearson UK. More are planned in 2011;

- Talk about our guidelines with our key paper suppliers when we meet and as part of our contract discussions;

- Discuss our approach to paper purchasing with customers, environmental groups, investor analysts and other interested parties;

- Retain Forest Stewardship Council (FSC) chain of custody certification allowing their books to also carry the FSC label for Dorling Kindersley and Penguin in the UK;

- Have continued with the process of seeking to attain FSC chain of custody accreditation for our businesses in North America.

In addition to the standards we set ourselves through our paper purchasing guidelines, we also have a responsibility to use fewer resources where we can. This delivers both environmental benefits as well as cost savings. All our businesses that use paper are focused on improvements, here is one example:

Case study: Pearson North America – Schools

Our schools business has continued with its sustained campaign to improve its environmental efficiency. The achievements have been phenomenal, with its 2010 environmental programme helping to avoid the need for over 30,000 US tons of wood. That is over 200,000 trees. This was achieved through a series of initiatives including increased use of recycled fibre, a shift from free sheet to ground wood, a process that uses the entire tree including the bark and by reducing the weight of paper used in our books. Other green initiatives saw the elimination of over 66,000 pounds of plastic and 5,000 gallons of cover coating used.

Less than 0.5% of Pearson products are printed by our own operations. We have two small digital print operations in the US. These operations provide short-run and print-on-demand products, typically custom client applications.

In addition to our general approach to supplier responsibility, we ask our printers for additional reporting in key areas. We have for a number of years maintained a printer register of environmental performance. Last year, we set a target to completely review our approach with Pearson International piloting a new process.

This year, the Pearson International model will be adopted globally.

Distribution and Shipping

We outsource distribution and shipment of our products to third party carriers.

Our books are produced around the world, requiring shipment from the printers to our Distribution Centres. Maximising the container load is an important measure of environmental efficiency. A review in 2005 of the performance of different parts of the business identified an opportunity to consolidate shipments and thus maximise container loads.

Case study: Pearson International – Surveying our printers

Pearson International surveyed all its printers and binders which supplied goods valued at £100,000 and above or local currency equivalent. Printers were based in the UK, Europe, North and Latin America, Africa and Asia. The survey covered:

- whether the printer uses a recognised system for environmental management and health and safety;

- measurement and reduction policies for water, ink, solvents, alcohol, energy and waste.

Working with World Transport Agency (WTA), one of our main shipping agencies we established a process in 2006 to measure the carbon footprint associated with the shipping of our books across 12 key routes covering over 90% of books shipped. In order to calculate the carbon footprint, WTA worked with shipping companies and the Carbon Neutral Company to develop new methodologies to measure carbon intensity through a tonnes CO2 per Container measure. Pearson was the first company to engage with WTA to apply this methodology to our shipments.

Road

Our main road distributors in the UK and Europe are DHL for books and TNT for the Financial Times. We meet regularly with our distributors and in January 2011, we were featured as a good case study in a seminar hosted by DHL on environmental trends in the publishing industry.

In the US, we similarly outsource distribution, with UPS being the recently adopted main provider of parcel service. We monitor environmental performance as part of the contractual arrangements. One of the criteria for selecting UPS was its environmental performance.

Inventory management is an important area of impact for us. During 2010, we have developed performance metrics in that area covering all book businesses worldwide. For 2011, we will be considering how to externally report on progress

Working with industry partners

We believe that working with industry partners in setting social and environmental standards is a responsible approach to improving global practice. This approach has many benefits including:

- Reducing the burden on the supplier – they only complete one audit instead of several, different processes. This is particularly important for smaller suppliers;

- In many of the markets where we operate, Pearson alone has insufficient influence with suppliers to enforce a set of standards;

- The sector working together helps set terms of trade and reinforce the importance of non‑financial measures of performance.

- Our three most important industry initiatives are:

- We were a founder member of the group of publishing companies in the UK that established PreLIMS – a common social accountability standard;

- We are a member of the World Wildlife Fund (WWF) Forest & Trade Network and through this group, work with WWF and other company members to improve environmental standards of paper purchase;

- Helped found Publishers database for Responsible Environmental Paper Sourcing (PREPS), an industry collaboration to map the environmental characteristics of paper.

Both PREPS and PreLIMS were initially a UK initiative; however, Pearson businesses were the first to adopt these globally.

Plans

| 2011 plans | |

|---|---|

| Paper | Complete the process of securing Forest Stewardship Council (FSC) accreditation across our businesses in North America |

| Supplier relationship management |

As part of a project to build a comprehensive global vendor relationship management system comprising a web-based portal and suite of data-marts, we will incorporate corporate responsibility metrics and supplier certifications where appropriate. |

| Printer | Extend the printer survey piloted by Pearson International to printers serving Pearson North America, the FT and Penguin during 2011. Pearson International will use its survey printer findings to inform its priorities for seeking improvements |

| Inventory management | Review current internal performance metrics and our approach to external reporting in this area |